Types of Mud Pumps for Drilling Rigs: Essential Solutions for Your Projects

Selecting the right mud pump for your drilling rig is essential for optimizing efficiency and performance in your drilling operations. With extensive experience in the industry, I emphasize the importance of choosing the appropriate pump type to suit your needs. Whether you require a triplex pump for high-pressure tasks or a duplex pump for greater versatility, each type serves a specialized function. At Baoji Mengtai Petroleum Machinery Co., Ltd., we provide a variety of mud pumps tailored to meet the diverse demands of our clients. Our equipment is engineered for reliability and durability, enabling you to handle challenging conditions effectively. We are committed to delivering high-quality products that align with your operational objectives, ensuring that you can achieve enhanced drilling efficiency.Key Methods For Types Of Mud Pump For Drilling Rig Industry Giant Trusted by Pros

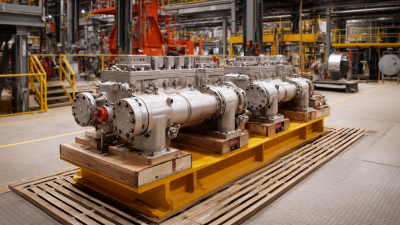

In the drilling rig industry, mud pumps are essential for maintaining optimal performance during drilling operations. Understanding the various types of mud pumps and their unique applications can greatly enhance efficiency and reliability in drilling projects. There are mainly three types of mud pumps: centrifugal pumps, positive displacement pumps, and diaphragm pumps. Each type offers distinct advantages depending on the specific requirements of the drilling environment. Centrifugal pumps are favored for their ability to move large volumes of fluid quickly, making them ideal for operations that require high flow rates. Positive displacement pumps, on the other hand, excel at maintaining consistent pressure, making them suitable for situations where precise fluid delivery is critical. Diaphragm pumps, known for their versatility and ability to handle abrasive materials, are an excellent choice for more challenging drilling conditions. Selecting the appropriate pump type can lead to significant improvements in productivity and cost-effectiveness for projects aimed at meeting stringent drilling schedules. As global procurement becomes increasingly competitive, understanding the intricacies of mud pumps can provide a substantial advantage for companies in the drilling rig industry. Focusing on innovation and reliability in equipment selection not only ensures compliance with industry standards but also fosters trust among stakeholders. By investing in high-quality solutions tailored to the specific demands of the drilling environment, companies can establish long-lasting relationships within the global marketplace and enhance their operational success.

Key Methods For Types Of Mud Pump For Drilling Rig Industry Giant Trusted by Pros

| Pump Type | Description | Max Flow Rate (GPM) | Max Pressure (psi) | Typical Applications |

|---|---|---|---|---|

| Triplex Pump | Three piston design, offering high efficiency and consistent performance. | 200 | 5000 | Oil & gas drilling, water well drilling. |

| Duo-Plex Pump | Two piston design, known for simplicity and durability. | 150 | 3500 | Geothermal drilling, construction applications. |

| Polymer Pump | Designed for pumping viscous fluids or polymers. | 120 | 4000 | Enhanced oil recovery, environmental applications. |

| Single-Piston Pump | Simple design, mainly used for low flow applications. | 50 | 1500 | Mud circulation in small drilling projects. |

Best Practices For Types Of Mud Pump For Drilling Rig Industry Giant Dominates

M

Matthew King

Amazing quality! The professionalism of their customer service representatives is commendable.

24 June 2025

A

Ava Roberts

This purchase was perfect! Their customer service personnel showcased great professionalism.

04 July 2025

A

Alexander Stewart

Excellent craftsmanship! Their customer service representatives are very proficient.

30 May 2025

L

Lily Walker

Exceptional quality! Their service personnel provide outstanding support.

15 June 2025

E

Eli Washington

This product is outstanding! Exceptional service and follow-up.

21 May 2025

C

Chase Edwards

Quality product with great performance! The after-sales service is exceptional.

15 June 2025