Pulley and Shaft Assembly: Durable Solutions for Mechanical Design and Efficiency

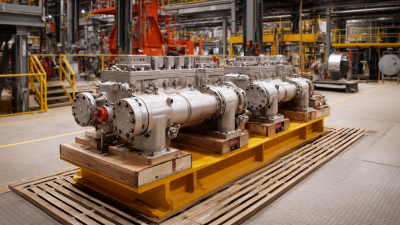

Our Pulley and Shaft Assembly is engineered for exceptional performance and long-lasting durability, tailored to meet the rigorous demands of the petroleum industry. Crafted from high-quality materials, this assembly ensures superior wear resistance, resulting in an extended service life. By minimizing downtime, our product enhances productivity for businesses of all sizes. At Baoji Mengtai Petroleum Machinery Co., Ltd., I personally oversee the manufacturing process, guaranteeing that every unit adheres to the highest quality standards. Experience the reliability and efficiency that your operations require with our dependable Pulley and Shaft Assembly.

7 Key Tips To Pulley And Shaft Assembly From Concept to Delivery For the Current Year

When it comes to the manufacturing of pulley and shaft assemblies, precision, quality, and timely delivery are paramount. As a seasoned player in the petroleum machinery sector, we understand the intricacies involved in moving from concept to delivery. Here are seven essential tips for global buyers looking to streamline this process. First, establish a clear design specification. Collaborate closely with suppliers to ensure that every detail—from material selection to dimensional tolerances—is agreed upon early in the development phase. This proactive approach mitigates misunderstandings and reduces costly rework. Second, leverage advanced manufacturing technologies. Automated processes can enhance precision and accelerate production timelines, ensuring that the final assemblies meet stringent quality standards. Third, prioritize supply chain transparency. Maintaining open lines of communication with suppliers and logistics partners fosters a collaborative environment, enabling swift resolutions to any potential issues. Fourth, implement rigorous testing protocols throughout the assembly process to ensure that every unit functions optimally. Finally, embrace an agile response strategy to adapt to changing market demands. By planning for flexibility in production schedules and inventory, buyers can ensure a steady supply of high-quality products that meet their requirements. Keeping these key considerations in mind will facilitate a smoother transition from concept to delivery, ultimately driving greater satisfaction among global clients.

7 Key Tips To Pulley And Shaft Assembly From Concept to Delivery For the Current Year

| Tip Number | Tip Description | Key Considerations | Implementation Timeline |

|---|---|---|---|

| 1 | Conduct Thorough Research | Identify existing solutions and technologies | 1 month |

| 2 | Define Clear Objectives | Set measurable goals for assembly | 2 weeks |

| 3 | Choose the Right Materials | Evaluate strength, durability, and cost | 3 weeks |

| 4 | Create Detailed Design Specifications | Include all technical requirements | 4 weeks |

| 5 | Prototype and Test Components | Ensure functionality and fit | 5 weeks |

| 6 | Finalize Assembly Process | Develop step-by-step assembly guide | 2 weeks |

| 7 | Review and Optimize | Gather feedback and make improvements | Ongoing |

Best Way To Pulley And Shaft Assembly Market Leader Exceeds Industry Benchmarks

M

Matthew King

Amazing quality! The professionalism of their customer service representatives is commendable.

24 June 2025

S

Sophie Parker

Absolutely great! The support personnel were friendly and extremely competent.

16 May 2025

E

Ethan Edwards

This item is of remarkable quality. The after-sales service was prompt and helpful.

25 May 2025

L

Lily Walker

Exceptional quality! Their service personnel provide outstanding support.

15 June 2025

A

Audrey Scott

Remarkable quality! I was thoroughly impressed with the after-sales service.

29 May 2025

H

Henry Robinson

This purchase was well worth it! The service staff was incredibly helpful.

10 June 2025