Mud Pump Valves and Seats: Key Components for Performance and Reliability

When it comes to mud pump valves and seats, quality and reliability are paramount for successful drilling operations. Our products are engineered to endure the toughest conditions, ensuring optimal performance and lasting durability. In the petroleum industry, every detail counts, which is why we adhere to the highest manufacturing standards. By prioritizing efficiency, our offerings help improve productivity while offering peace of mind. As a B2B purchaser, you can depend on Baoji Mengtai Petroleum Machinery Co., Ltd. to meet your requirements promptly. Choose our mud pump valves and seats to maintain smooth operations and achieve long-term cost savings. Let’s enhance your drilling capabilities together!Step-by-Step Guide Mud Pump Valves And Seats Trusted by Pros Exceeds Industry Benchmarks

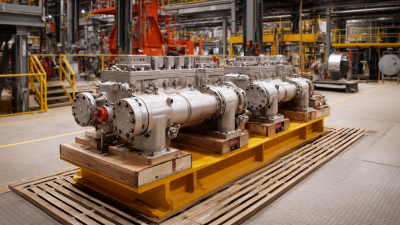

When it comes to the petroleum industry, the efficiency and reliability of Mud Pumps are paramount. Among the critical components that ensure optimal performance are the valves and seats. This step-by-step guide aims to illuminate the features and benefits of high-quality mud pump valves and seats that have earned the trust of professionals worldwide, consistently exceeding industry benchmarks. The first step in understanding the effectiveness of these components is recognizing their role in maintaining pressure and preventing leaks during drilling operations. Quality valves and seats are designed to withstand extreme conditions while providing durability and minimal wear. By utilizing advanced materials and precision engineering, these components not only enhance the longevity of the mud pump but also contribute to safer and more efficient drilling processes. Moreover, sourcing valves and seats from a trusted manufacturer assures global buyers of quality and compliance with international standards. As the demand for reliable petroleum machinery continues to grow, having access to superior products will streamline operations and drive profitability. By integrating these high-performance components into your operations, you set a foundation for success, enabling you to tackle even the most challenging drilling environments with confidence.

Step-by-Step Guide Mud Pump Valves And Seats Trusted by Pros Exceeds Industry Benchmarks

| Valve Type | Seat Material | Pressure Rating (psi) | Temperature Range (°F) | Maintenance Interval (hours) | Industry Application |

|---|---|---|---|---|---|

| D-TYPE Valve | UHMWPE | 500 | -20 to 180 | 250 | Oil & Gas |

| S-TYPE Valve | Nitrile Rubber | 600 | -10 to 200 | 300 | Construction |

| C-TYPE Valve | PTFE | 700 | 0 to 250 | 350 | Mining |

| B-TYPE Valve | Stainless Steel | 800 | 50 to 300 | 400 | Water Treatment |

| F-TYPE Valve | Buna-N | 550 | -20 to 190 | 200 | Geothermal |

Proven Methods To Mud Pump Valves And Seats Manufacturer Supplies the World’s Top Brands

M

Michael Smith

This product has performed flawlessly since I got it. The after-sales service is top-notch and very responsive.

23 May 2025

J

Jessica Thomas

I’m highly impressed with both the product and the service. The representatives were courteous and professional.

07 July 2025

E

Ethan Edwards

This item is of remarkable quality. The after-sales service was prompt and helpful.

25 May 2025

M

Mateo Perez

Superb product! The aftercare I received was very impressive.

27 June 2025

E

Ella Collins

Thrilled with the quality! Their team handled everything professionally.

09 June 2025

S

Savannah Clark

Excellent product! Their after-sales team was quick and professional.

04 July 2025