Mud Pump Safety Relief Valve: Key Insights for Enhanced Performance and Safety

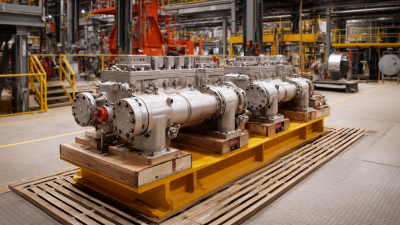

The Mud Pump Safety Relief Valve is vital for maintaining safety and efficiency in drilling operations. Engineered to regulate pressure levels, this valve effectively prevents overpressure situations that can result in equipment damage and safety risks. Its durable construction ensures exceptional performance reliability across various drilling applications, coupled with an intuitive installation process. Baoji Mengtai Petroleum Machinery Co., Ltd. demonstrates a strong commitment to quality, making this valve a trusted choice within the industry. Implementing this safety solution not only enhances operational reliability but also minimizes potential risks in drilling projects. Prioritizing safety and efficiency together is essential for successful drilling operations.Insider Tips For Mud Pump Safety Relief Valve More Than a Supplier - A Partner Sets the Industry Standard

When it comes to the petroleum industry, ensuring the safety and reliability of equipment is paramount. A crucial component in this equation is the mud pump safety relief valve, a product that not only requires precision engineering but also a comprehensive understanding of its operational environment. For global buyers, sourcing these valves should go beyond simply finding a supplier; it’s about forming a partnership that prioritizes safety and standards. A solid partner will provide insights and tips that extend beyond the basic functionality of the product. Quality control procedures, proper installation techniques, and regular maintenance schedules should be emphasized. Importantly, selecting a manufacturer that follows industry standards can mitigate risks associated with mud pump failures, which can lead to costly downtime. Additionally, a knowledgeable partner will offer support in training staff and understanding specific site requirements, ensuring that safety measures are not just adhered to but are optimized for the unique conditions encountered in various fields. Investing in a relationship with a partner who is committed to continuous improvement and innovation in their products can lead to enhanced operational efficiency and longevity of equipment. Such collaboration ensures that both parties are aligned on safety protocols and performance expectations, establishing benchmarks that keep the entire supply chain robust. In this rapidly evolving industry, your choice of partner can define your success and commitment to safety standards.

Insider Tips For Mud Pump Safety Relief Valve More Than a Supplier - A Partner Sets the Industry Standard

| Tip Category | Tip | Importance Level | Frequency of Issues |

|---|---|---|---|

| Maintenance | Regularly inspect and clean the relief valve to prevent blockages. | High | Monthly |

| Training | Provide comprehensive training for operators on valve safety protocols. | Medium | Quarterly |

| Monitoring | Use pressure gauges to continuously monitor the performance of the relief valve. | High | Daily |

| Replacement | Replace any corroded or damaged valves immediately to prevent failures. | Critical | As needed |

| Compatibility | Ensure that replacement valves meet the manufacturer's specifications for compatibility. | High | Bi-annual |

Popular Mud Pump Safety Relief Valve Service Backed by Expertise Your Trusted OEM Partner

I

Isabella Hill

Top-notch quality and great service. The representatives really know their stuff!

14 June 2025

M

Mia Nelson

Quality that stands out! The support team was quick to respond and very knowledgeable.

16 June 2025

L

Lucas Campbell

The quality is exceptional! Customer service was quick, professional, and responsive.

01 July 2025

J

Jason Hughes

High standards in both product and service. The support team is incredibly competent.

09 June 2025

E

Ella Carter

Fantastic quality! I was amazed by the professionalism of the service team.

24 June 2025

C

Chloe Long

This purchase is a winner! Their customer service made the experience seamless.

10 June 2025