01

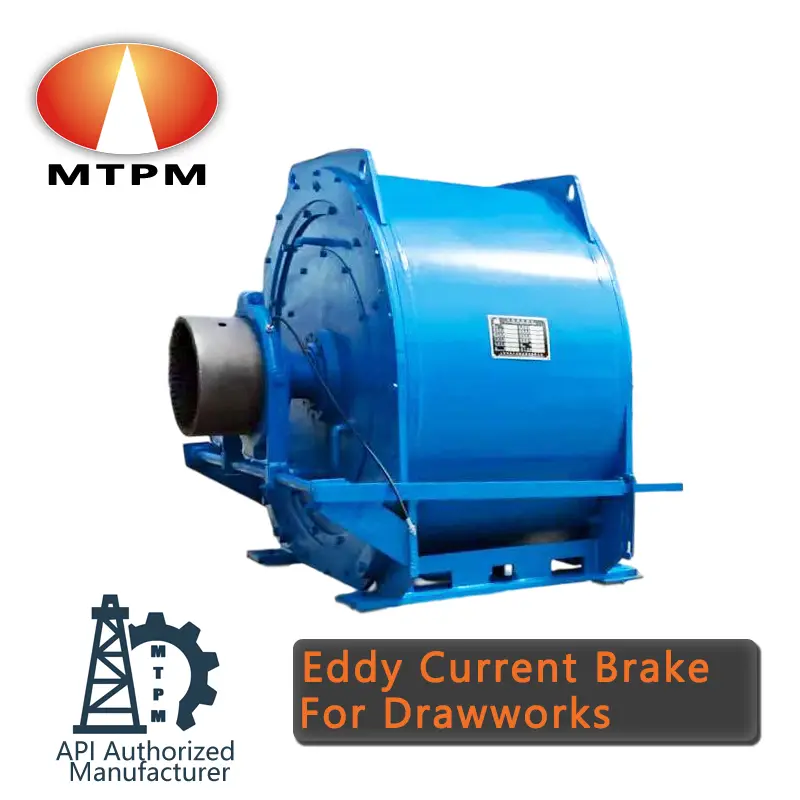

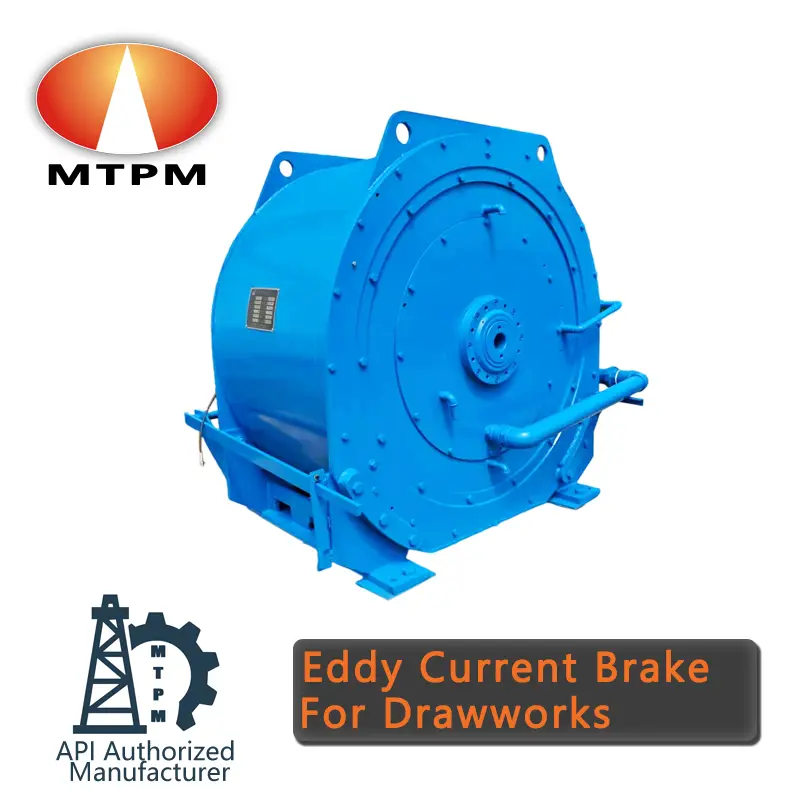

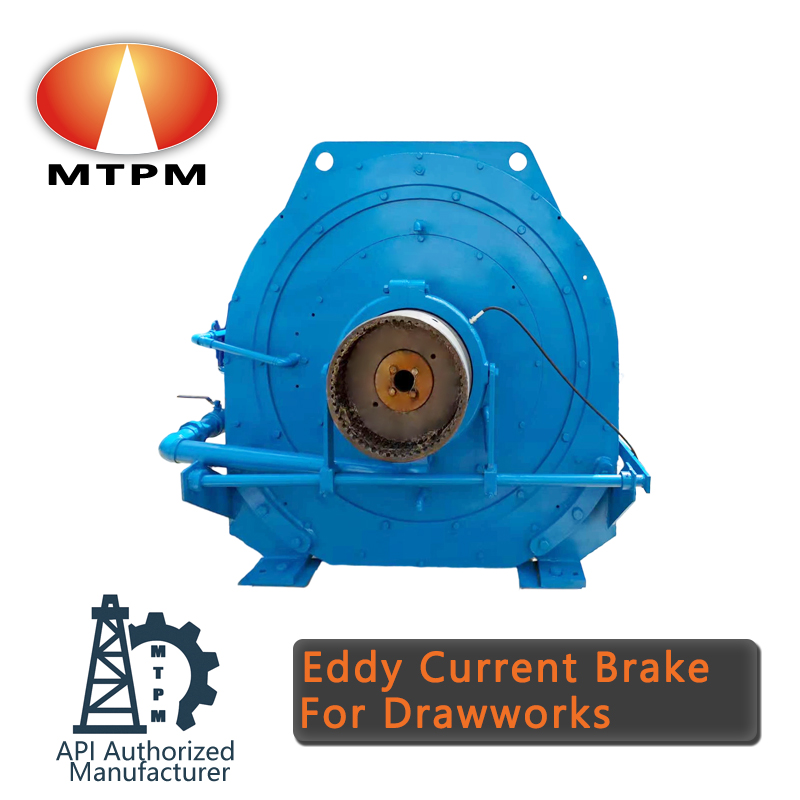

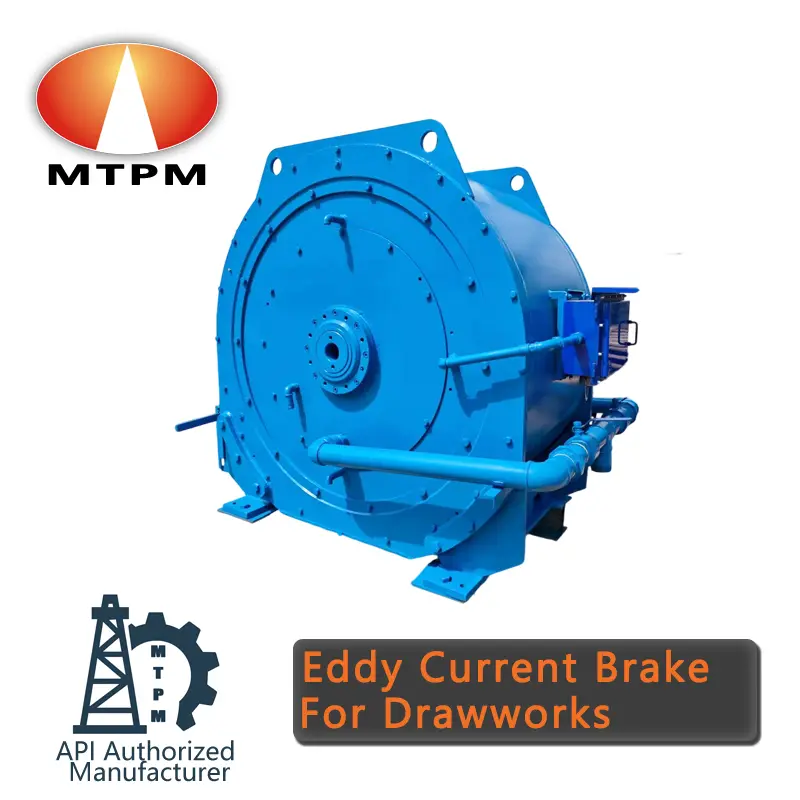

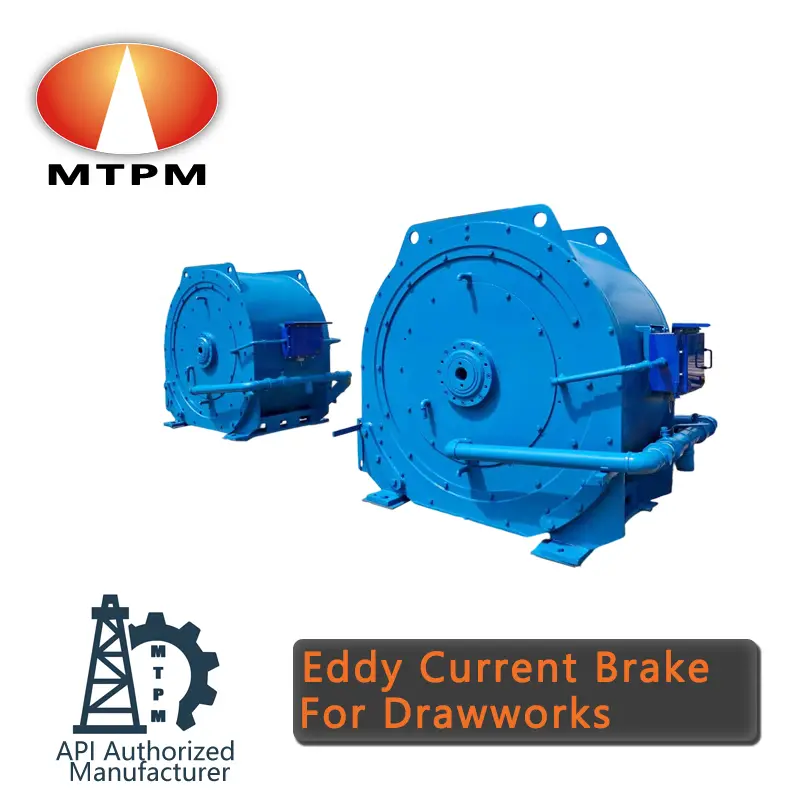

MTDSF-50 Electromagnetic Eddy Current Brake for Land and Offshore Drilling Rigs Drawworks

Product Specifications

Product name |

Electromagnetic Eddy Current Brake,Eddy Current Brake (ECB),Electromagnetic Brake |

Chinese Model |

MTDSF-50 |

Rated Braking Torque |

55,000 N·m |

Applicable Drilling Depth (with 5″ Drill Pipe) |

5,000 m |

Number of Coils |

4 |

Rated Resistance per Coil |

6.54 Ω ±10% |

Insulation Class |

Class H |

Coil Connection |

Series-Parallel |

Maximum Excitation Power |

15 kW |

Maximum Excitation Current |

45 A |

Cooling Airflow |

12,000 m³/h |

Weight (including control system) |

7,280 kg |

Overall Dimensions (mm) |

2598 * 1850 * 1613 |

Third party witness and inspection report available |

Bureau Veritas (BV), CCS, ABS, SJS etc. |

Product Features

The air-cooled electromagnetic eddy current brake, equipped with forced ventilation, retains the advantages of water-cooled designs,such as high braking torque and simple operation:

The cooling system is simplified, eliminating the need for large water tanks, pumps, and pipelines, while avoiding freezing problems in cold climates.

It prevents scaling and corrosion issues, ensuring that the air gap remains stable and braking torque remains reliable.

It avoids the risk of coil burnout caused by operator error in water-cooled systems (e.g., failing to start the water pump).

It eliminates failures caused by seal leakage, which can lead to coil damage and bearing breakdown in water-cooled brakes.

Continuous forced ventilation allows effective heat dissipation even after braking stops, unlike water-cooled brakes where cooling ceases once rotation ends, ensuring safer operation during drill-in.

Engineered for drilling rig safety systems, combining durability, safety, and compliance with API 7K,IEC,ISO 9001 and Chinese standards.

Product Details