01

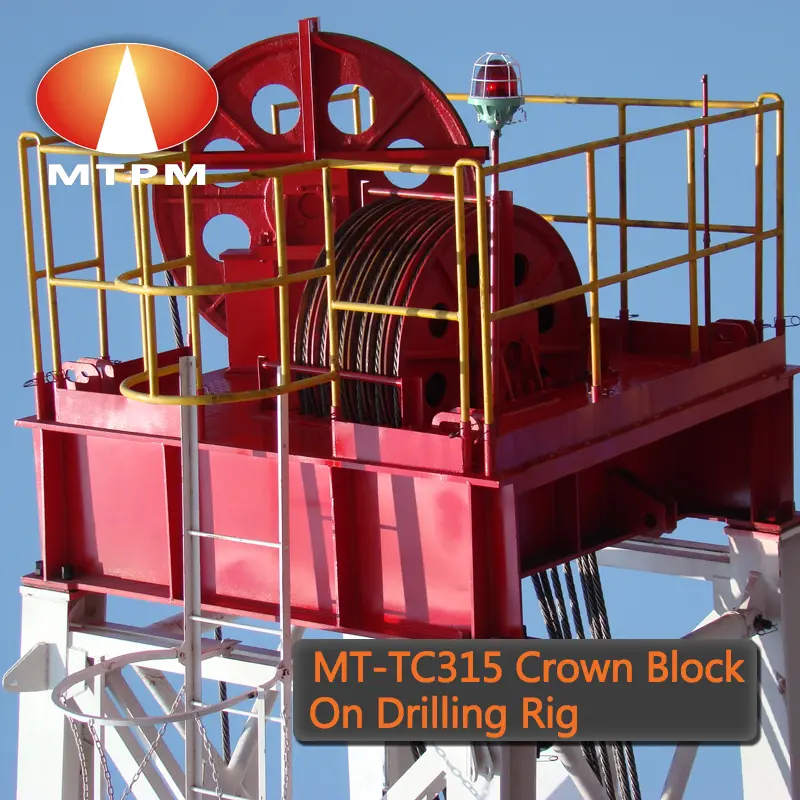

MT-TC Series Crown Block for Drilling Rigs

Product Specifications

|

Model |

MTTC90 |

MTTC170 |

MTTC225 |

MTTC315 |

MTTC450 |

|

|

Max.hook load(kN) |

900 |

1700 |

2250 |

3150 |

4500 |

|

|

Diameter of wire line (mm) |

26 |

29 |

32 |

35 |

38 |

|

|

O.D.of sheaves mm(in) |

762(30") |

1005(40") |

1120(44") |

1270(50") |

1524(60") |

|

|

Number of sheaves |

5 |

6 |

6 |

7 |

7 |

|

|

Overall dimension mm |

Length |

2317 |

2668 |

2668 |

3192 |

3410 |

|

Width |

2076 |

2460 |

2709 |

2783 |

2753 |

|

|

Height |

1577 |

1855 |

2469 |

2350 |

2420 |

|

|

Weight(KGS) |

2668 |

4540 |

6500 |

8500 |

11105 |

|

• Third party witness and inspection report available: Bureau Veritas (BV), CCS, ABS, SJS etc.

Compliance and Reliability

All MT-TC crown blocks are manufactured in full accordance with API Spec 4F (for drilling structures) and API Spec 8C (for drilling and production hoisting equipment). They also comply with the requirements of the Chinese industry standard SY/T 5527, ensuring safety and consistency with domestic regulations.

Each sheave in the crown block is individually certified to API Spec 8C(8C-0349), ensuring verified quality and performance under rated loads.

To guarantee long service life, the sheave grooves are subjected to quenching and surface hardening treatments, which greatly improve wear resistance and minimize deformation under heavy loads.

Each unit is inspected and tested to meet international safety requirements, offering drilling contractors a product that is both trustworthy and cost-efficient in long-term operation

Each sheave in the crown block is individually certified to API Spec 8C(8C-0349), ensuring verified quality and performance under rated loads.

To guarantee long service life, the sheave grooves are subjected to quenching and surface hardening treatments, which greatly improve wear resistance and minimize deformation under heavy loads.

Each unit is inspected and tested to meet international safety requirements, offering drilling contractors a product that is both trustworthy and cost-efficient in long-term operation

Product Features

• The crown block is equipped with wireline guide rods and rope retention plates, which effectively prevent the drilling line from jumping out of the sheave groove or slipping under dynamic loads.

• A safety chain protector is installed to enhance operational security, while an integrated maintenance gantry provides convenient access for sheave inspection and repair.

• Depending on drilling contractor requirements, MTPM can supply the crown block with optional bailing pulleys and auxiliary pulley assemblies, expanding its application range.

• The product design also allows the crown block sheaves to be interchangeable with those of the traveling block when they share the same hook load rating, simplifying maintenance and reducing spare parts inventory.

• With these features, the MT-TC crown block represents a well-balanced solution that combines durability, operational safety, and adaptability to various rig configurations.

Engineered for drilling rig hoisting systems, combining durability, safety, and compliance with API and Chinese standards.

• A safety chain protector is installed to enhance operational security, while an integrated maintenance gantry provides convenient access for sheave inspection and repair.

• Depending on drilling contractor requirements, MTPM can supply the crown block with optional bailing pulleys and auxiliary pulley assemblies, expanding its application range.

• The product design also allows the crown block sheaves to be interchangeable with those of the traveling block when they share the same hook load rating, simplifying maintenance and reducing spare parts inventory.

• With these features, the MT-TC crown block represents a well-balanced solution that combines durability, operational safety, and adaptability to various rig configurations.

Engineered for drilling rig hoisting systems, combining durability, safety, and compliance with API and Chinese standards.

Product Details