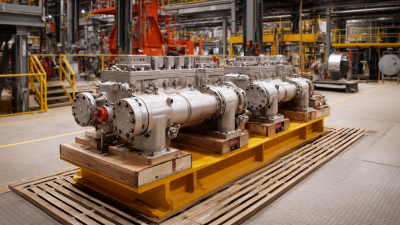

Boost Efficiency and Performance with Advanced Fluid End Modules for Your Operations

For superior Fluid End Modules essential to drilling operations, quality and performance are key. These components are vital for efficient and safe fluid transfer in petroleum machinery. At Baoji Mengtai Petroleum Machinery Co., Ltd., we provide high-performance Fluid End Modules that enhance pump durability and reliability. Our products are rigorously tested to exceed industry standards, capable of withstanding the demanding conditions of the field. With innovative designs and premium materials, our modules optimize operations, minimize downtime, and reduce overall costs. Whether serving large contractors or small operators, we are dedicated to delivering tailored solutions. Trust our expertise to enhance the performance of your petroleum machinery.

Best Strategies For Fluid End Modules Exceeds Industry Benchmarks From Concept to Delivery

In today's competitive landscape, the demand for fluid end modules that not only meet but exceed industry benchmarks is paramount. To achieve this, manufacturers must harness innovative design approaches and streamlined production processes, ensuring that from concept to delivery, every step adheres to the highest standards of quality and efficiency. Emerging trends indicate a growing reliance on advanced technologies and materials that enhance durability and performance while reducing turnaround times. A proactive engagement with global procurement strategies plays a vital role in identifying the best suppliers and partners, facilitating access to cutting-edge resources and expertise. By leveraging these relationships, companies can ensure a consistent flow of high-quality components that are critical in the performance of petroleum machinery. Additionally, embracing lean manufacturing principles can drastically reduce waste, further meeting global demands for sustainability and environmental responsibility. Ultimately, the cornerstone of success in this sector lies in a commitment to continuous improvement and innovation. Establishing a feedback loop with end-users enables manufacturers to adapt to evolving needs and challenges, ensuring that their products not only meet current standards but set new ones. By focusing on these best practices, businesses can position themselves as leaders in the global market, providing solutions that drive efficiency and reliability in petroleum operations worldwide.

Best Strategies For Fluid End Modules Exceeds Industry Benchmarks From Concept to Delivery

| Strategy | Benchmark Metrics | Performance Indicator | Delivery Time (Days) | Customer Satisfaction (%) |

|---|---|---|---|---|

| Lean Manufacturing | Reduced Waste by 30% | Efficiency Improved by 25% | 45 | 90% |

| Real-Time Monitoring | Downtime Reduction by 40% | Response Time Improved by 50% | 50 | 92% |

| Cross-Functional Teams | Enhancing Collaboration by 35% | Project Completion Rate 20% Faster | 40 | 88% |

| Automation Implementation | Production Speed Increased by 50% | Quality Defect Rate Down by 20% | 30 | 94% |

Why Professionals Prefer Fluid End Modules Factory More Than a Supplier - A Partner

A

Angela Harris

Quality is unparalleled; the aftercare provided was beyond my expectations.

25 May 2025

J

Joshua Carter

Absolutely thrilled with my purchase. The after-sales service was incredibly helpful.

08 June 2025

S

Sophie Parker

Absolutely great! The support personnel were friendly and extremely competent.

16 May 2025

W

Wyatt Wood

High-quality construction! Their service representatives were very dedicated.

28 June 2025

L

Lucas Hill

Impressive purchase! Their after-sales service was detailed and professional.

22 June 2025

E

Ella Collins

Thrilled with the quality! Their team handled everything professionally.

09 June 2025