Key Features of Drilling Rig Crown Blocks for Efficient Operations

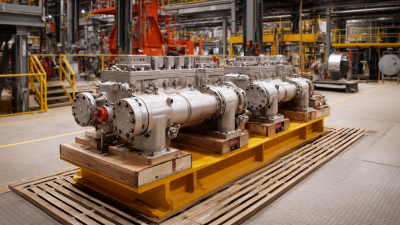

Elevate your drilling operations with our exceptional Drilling Rig Crown Block. Designed specifically for the petroleum industry, this crown block combines reliability and high performance to meet the rigorous demands of drilling tasks. With its precise craftsmanship, it ensures seamless operations, minimizes downtime, and boosts productivity on-site. Investing in our Drilling Rig Crown Block means prioritizing not only equipment excellence but also enhanced operational efficiency. Connect with us to find out how we can effectively support your drilling projects!In-Depth Analysis of Methods Drilling Rig Crown Block Service Backed by Expertise Factory-Direct Excellence

In the ever-evolving landscape of petroleum machinery, the efficiency and reliability of drilling operations hinge significantly on the performance of critical components, one of the most vital being the crown block. As an integral part of The Drilling Rig, the crown block serves as a pivotal point for raising and lowering the drill string, and its serviceability directly impacts operational productivity and safety. A comprehensive analysis of the methods employed in crown block servicing reveals a spectrum of techniques that not only enhance performance but also extend the lifespan of this essential equipment. A cornerstone of effective crown block maintenance lies in the application of factory-direct excellence, which means sourcing parts and services directly from the manufacturer. This approach ensures that procurement is not only cost-effective but also leverages superior engineering expertise. Manufacturers with a robust track record in the petroleum industry provide invaluable insights into best practices for maintenance, inspections, and upgrades, effectively mitigating risks and minimizing downtime. With the right knowledge and technology, procurement professionals can benefit from tailored solutions that align with their operational needs, ultimately driving enhanced efficiency in drilling operations. Moreover, understanding the intricate details of crown block mechanics and servicing techniques fosters a more strategic approach in global procurement processes. By emphasizing quality and reliability over mere cost considerations, buyers can safeguard their investments and ensure seamless project execution. As they navigate the complexities of the global supply chain, partnering with leading manufacturers that prioritize excellence in every aspect of their operations will be crucial in meeting the demands of an increasingly competitive market. Embracing this mindset not only propels operational success but positions companies favorably for long-term growth in the petroleum sector.

In-Depth Analysis of Methods Drilling Rig Crown Block Service Backed by Expertise Factory-Direct Excellence

| Method | Advantages | Disadvantages | Expert Recommendations |

|---|---|---|---|

| Conventional Crown Block | Reliable operation, established technology | Higher maintenance costs, limited efficiency | Best for traditional drilling applications |

| Hybrid Crown Block | Combines benefits of traditional and modern tech | Complex installation, requires skilled personnel | Recommended for versatile drilling environments |

| Electric Crown Block System | Lower energy costs, reduced environmental impact | Higher initial investment, requires advanced infrastructure | Ideal for long-term operational efficiency |

| Digital Crown Block Monitoring | Real-time data analysis, predictive maintenance | Dependency on technology, potential data overload | Best for data-driven decision-making processes |

China Top Drilling Rig Crown Block Factory-Direct Excellence Custom Solutions,

L

Laura Wilson

The craftsmanship is outstanding. I felt supported by their knowledgeable staff whenever I had questions.

14 May 2025

R

Robert Martinez

This purchase has been a game-changer for my business. The after-sales service is exceptional.

08 June 2025

M

Mateo Perez

Superb product! The aftercare I received was very impressive.

27 June 2025

L

Leo Carter

Outstanding quality! Their customer service is quick and professional.

30 June 2025

R

Riley Nguyen

Exceptional quality and service! Their personnel truly care about their customers.

01 June 2025

I

Ian Johnson

I love this product! Their customer service team is always ready to assist.

03 July 2025