0102030405

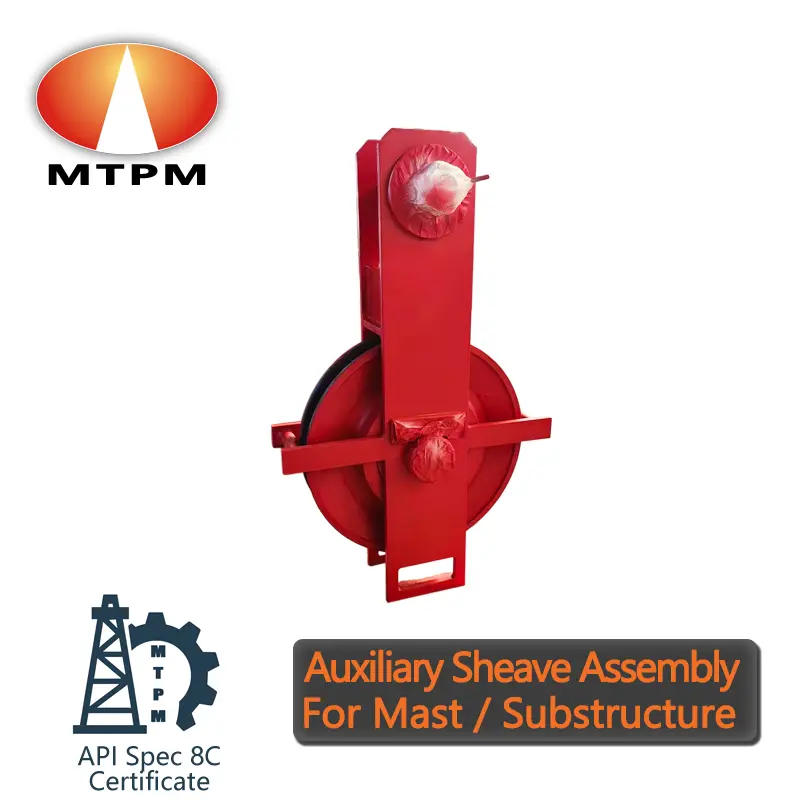

Auxiliary Sheave Assembly for Drilling Rigs

Product Specifications

| Product name | Auxiliary Sheave Assembly / Rig Auxiliary Pulley |

| Application | Typically used for redirecting wire rope during auxiliary lifting operations |

| Sheave OD | 400mm(15 3/4 inches) |

| Groove diameter | 16~24mm |

| Material | 45# Alloy Steel (forged and welded alloy steel with mechanical properties equivalent to JIS S45C / AISI 1045 or higher-grade structural steel) |

| Surface Treatment | Rope groove induction hardened for wear resistance |

| Temperature rating | -40°C to 120°C |

| Service life | 8~10 years in standard drilling environments. Induction-hardened grooves and alloy-steel construction extend fatigue resistance, while periodic inspection ensures long-term reliability in both primary and auxiliary hoisting applications. |

| Mounting Compatibility | Designed for mast structure attachment points or auxiliary hoisting brackets on common rig series such as ZJ30, ZJ40, ZJ50, and ZJ70. |

| Pre-delivery Inspection | 100% Magnetic Particle Testing (MT) 100% Ultrasonic Testing (UT) on critical welds and forged sections. |

| Standard | Produced under API 8C |

| Third party witness and inspection report available: Bureau Veritas (BV), CCS, ABS, SJS etc. | |

Product Features

HIGH OEM Interchangeability: Fully compatible with auxiliary sheave assemblies supplied by BOMCO, HH,LS NOV,RGand other leading rig manufacturers, offering a reliable replacement option for both domestic and international drilling operations.

Durable Forged-Welded Construction: The sheave body is formed using a forgedsteel blank welded to a reinforced housing, providing excellent load-bearing capacity and resistance to deformation under cyclic rope loads.

Heat-Treated Rope Groove:Mediumfrequency induction hardening enhances wear resistance, extending both the sheave lifespan and the working life of the wire rope.

Strict Quality Assurance: Every assembly undergoes MT and UT inspection before leaving the factory, ensuring the structural reliability required for hoisting applications.

All assemblies follow internal production standards aligned with API 8Cprinciples to ensure load integrity, safety, and long-term stability. Our API 8C certificate number : 8C-0349.

Source Manufacturer Advantages: With more than ten years devoted to sheave production, our factory provides stable supply, custom sizing options, and consistent quality for drilling contractors and OEM equipment builders.

MTPM Auxiliary sheave assemblies are classified as functional components within the hoisting and mast structure of land drilling rigs, rather than standalone equipment. They support the wire rope routing in the lifting system and help maintain proper tension, alignment, and operating stability. Although small compared with crown blocks or traveling blocks, these assemblies play a critical role in the overall reliability of the rig.

Our auxiliary sheaves are manufactured in a facility with more than a decade of production experience, using forging-welded construction and strict process control. Each sheave assembly is designed to integrate seamlessly with the mast, drawworks auxiliary hoisting systems, and structural lifting points on rigs ranging from 1000 HP to 3000 HP. We supply full interchangeability with sheave assemblies used by BOMCO, HH,LS NOV, and other major OEMs, supported by API 8C compliant quality control and documented inspection.

Contact for more details about the Auxiliary sheave assembly which used for HONGHUA,RG,RONGSHENG,EMSCO,LSNOV.

All product names, trademarks, and part numbers are used for identification purposes only and are the property of their respective owners. We are an authorized and recognized supplier, if you are looking for specific mud pump safety valve part numbers, please contact our sales team for detailed references or technical support.